African Logistics Services increase warehouse productivity by 256%

Manual warehousing brings a plethora of issues and drawbacks to companies still using them. It adds costs, makes you less agile, and is error-prone. With the added stress of finding labour, there has never been a better time to invest in a quality Warehouse Management System (WMS). What stops many logistics companies from proceeding is the amount of planning and implementation necessary for the switch. While it is a significant challenge, a good service provider can take that burden off you. Automated warehousing can transform your entire business, as it did for African Logistics Services (ALS).

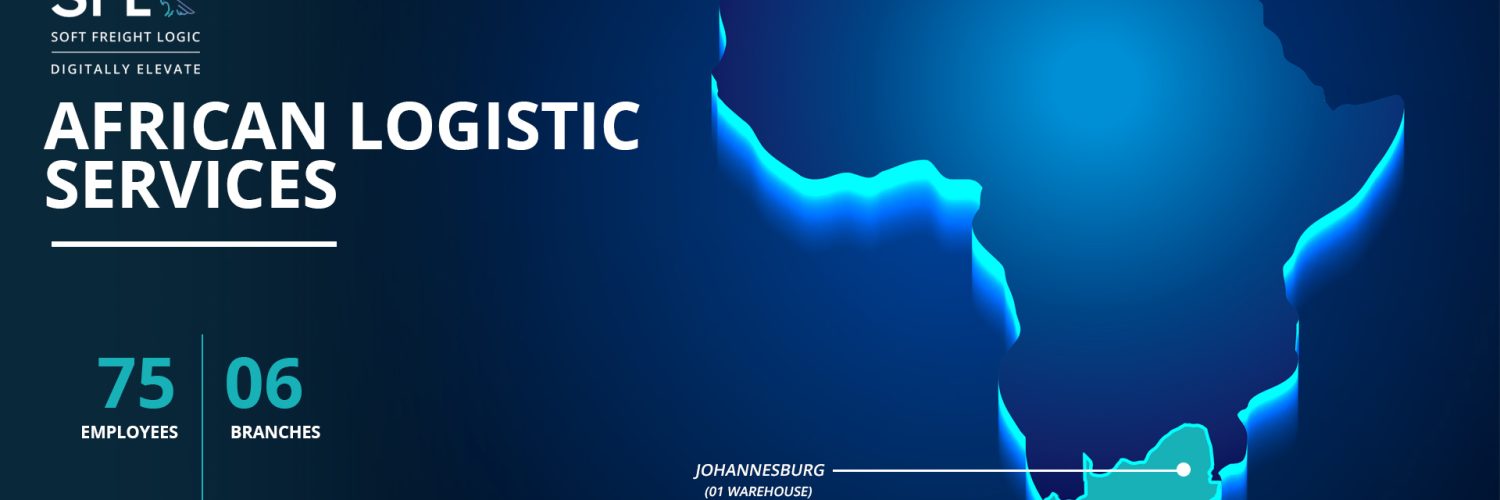

Customer overview

African Logistics Services is based in Durban, South Africa. With over 75 employees, they have six branches around South Africa. The company offers a full range of logistics and supply chain services that includes warehousing.

Their warehousing services are based on four warehouses – two in Cape Town and one in Durban and Johannesburg. They also operate two bonded warehouses in Durban.

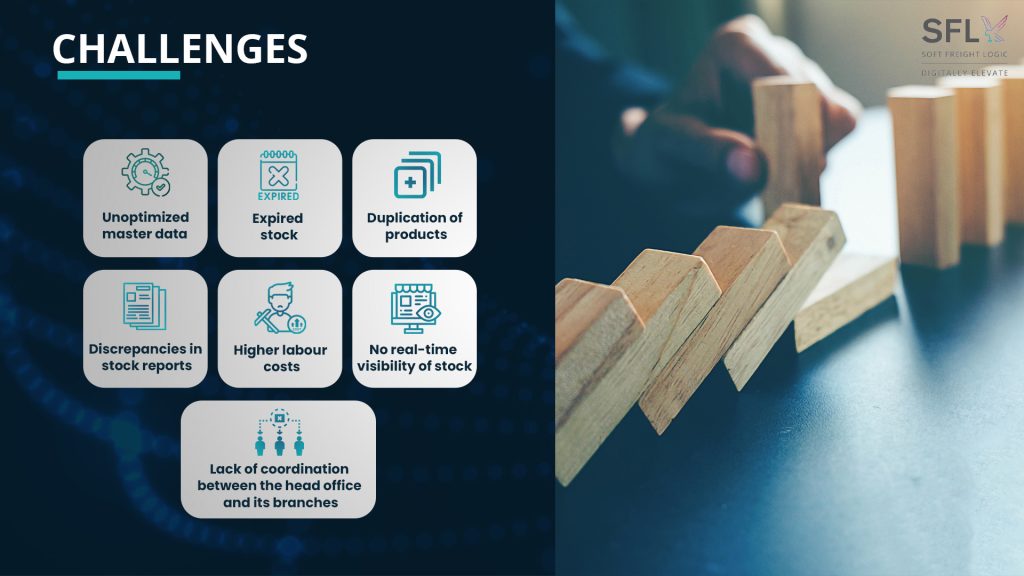

Challenges

ALS has achieved considerable growth due to their professionalism and customer-focused approach. However, their warehouses operated manually with record-keeping done via pen and paper.

This led to human errors. Master data was not being maintained optimally. Manual updating of inventory led to expired stock, duplications of products, and discrepancies in stock reports. The warehouse managers were forced to recheck physical stock and storage charges manually before raising monthly bills.

The manual operations also made it harder to have standard operating procedures (SOPs). An approval matrix was not being followed and the coordination between the head office and branches was poor. The operations team had two jobs to do if the stock had to be exported from the warehouse or vice versa. Receiving blind cargo was a nightmare.

As a consequence, labour costs and overtime rose. Worst of all, the suppliers’ clients had no way of getting real-time updates about their goods. This and discrepancies between stock reports and receipt reports led suppliers to no longer work with ALS.

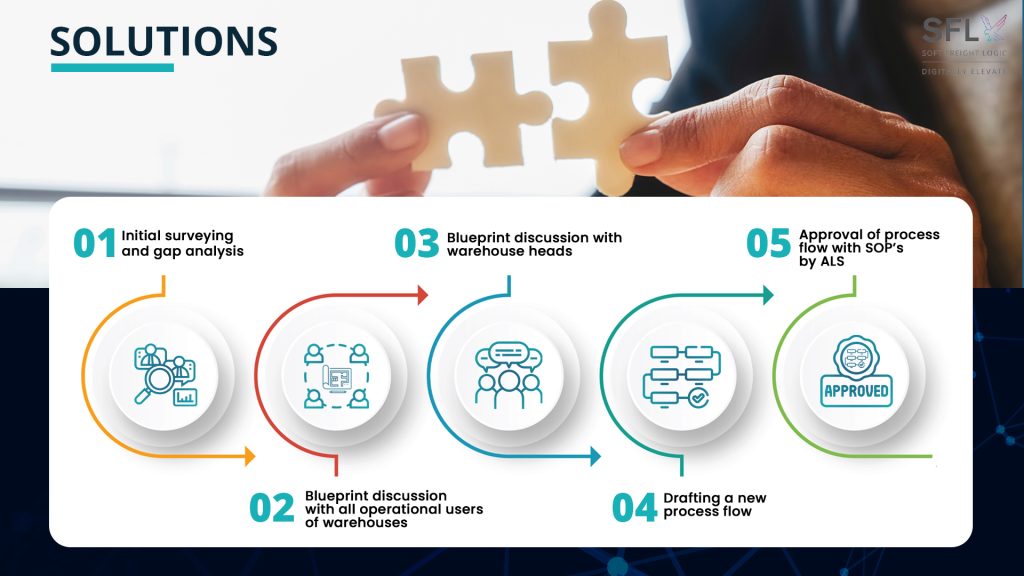

Solutions

After evaluating several WMSs and service providers, ALS chose CargoWise implemented by Soft Freight Logic (SFL). The main reason for their choice was the comprehensive nature of CargoWise WMS and the expertise SFL has with CargoWise solutions.

SFL took two weeks to thoroughly understand all the issues involved. The auditing of master data and duplicate product codes were key challenges. ALS was also using an open floor plan with no defined areas and locations, leading to inefficiencies. The transfer of the current stock inventory from the legacy system to CargoWise was another major change.

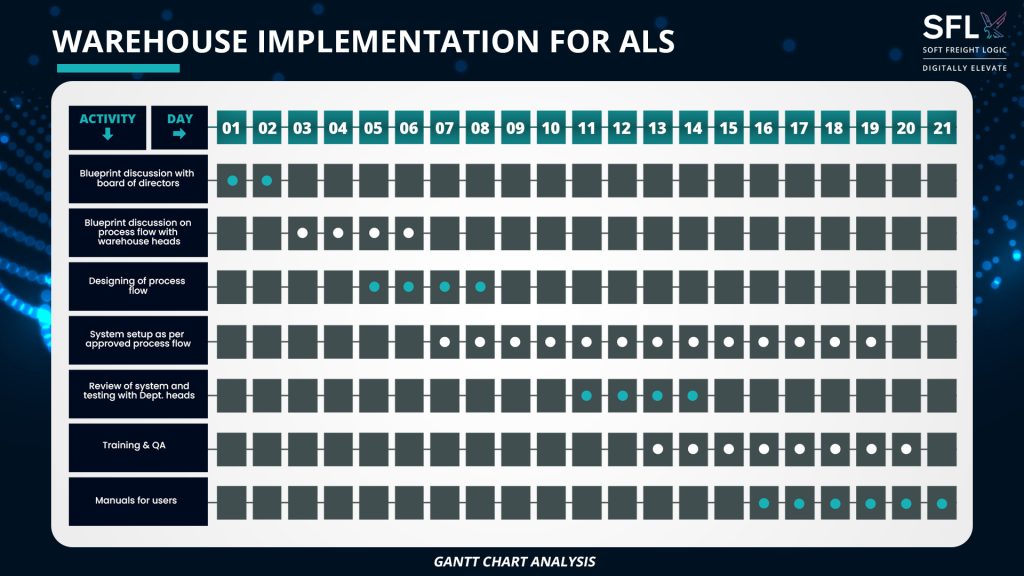

The process SFL and ALS followed for implementing CargoWise WMS are as follows.

- Initial surveying and gap analysis

- Blueprint discussion with all operational users of warehouses

- Blueprint discussion with warehouse heads

- Drafting a new process flow

- Approval of process flow with SOPs by ALS

After the process flow was finalised, SFL created a Gantt chart together with ALS. Implementation was first done at one warehouse as it was a complete change of orders.

Results

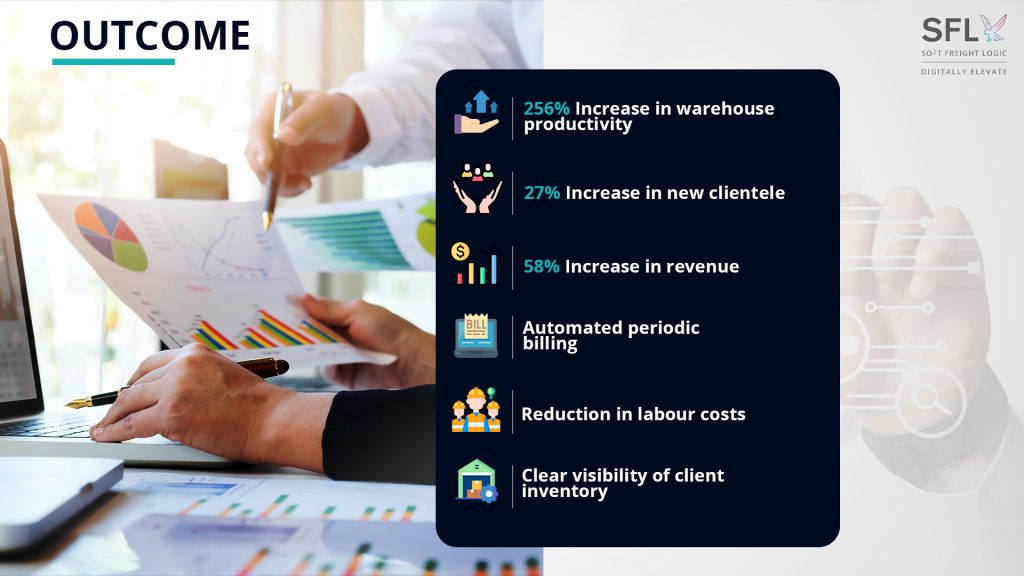

As a result of implementing CargoWise WMS, ALS transformed its entire business. The warehouses which bled money now have become a revenue centre.

After the implementation, stocks managed have increased by 256%. There is now a standard SOP and no paperwork. Daily tasks are converted into the task system. Stock reports are prescheduled and system-generated.

Periodic billing is automated at the end of the month. Correct locations of the warehouse are used for storage by the staff. This has led to a great reduction in maintenance and labour costs.

Instead of losing clients, new client onboarding has increased by 27%. Transfer of stocks is now easily done. So are packaging and repacking.

Clients get the on-time status of their inventory, providing them assurance. The overall revenue of the company has increased by 58%, with warehousing services being the most profitable.

Complete turnaround

ALS first implemented CargoWise WMS in one warehouse. Soon, they implemented it in all their warehouses as the system completely turned things around.

It is rare in business to make everyone happy. But the WMS made life easier for staff, made clients happier, and made the company more money. An all-around win-win.

If you have been considering or exploring options to switch to an automated system of warehousing, get in touch with us today for a free consultation. We will assist you in assessing your needs and help you choose the right solution.