We see how much the world has evolved during this pandemic. There has been an acceleration in the usage of technology that was always there but just underutilised.

Logistic companies are known for mundane tasks and an accumulation of paperwork. Whilst the demand in e-commerce increased which put immense pressures on the Logistic and Supply Chain Industry.

It is evident that along with technological advancements finding quality skills is crucial to ensure operations are run smoothly.

According to McKinsey, the successful implementation of AI has helped businesses improve logistics costs by 15%, Inventory levels by 35%, and service levels by 65%.

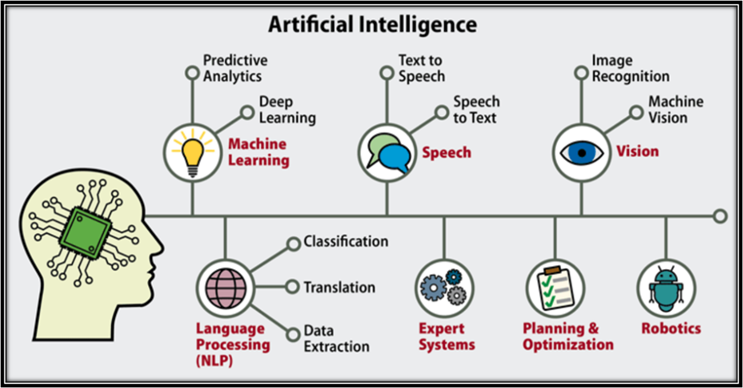

What is AI technology?

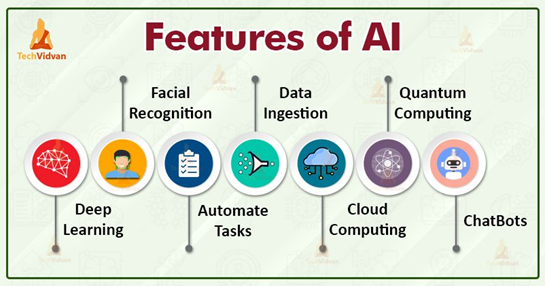

The definition of artificial intelligence is the theory and development of computer programs that are able to do tasks and solve problems that usually require human intelligence. Things like visual perception, speech recognition, decision-making, and word translation are all things that would normally need human intelligence, but now computer programs are able use their intelligence and capability to solve these tasks.

There are many ways to implement AI into the supply chain and into the logistics sector. It improves logistics processes and reduces costs. It also plays a major role in automating routine tasks to improve the speed and accuracy in numerous back-office applications.

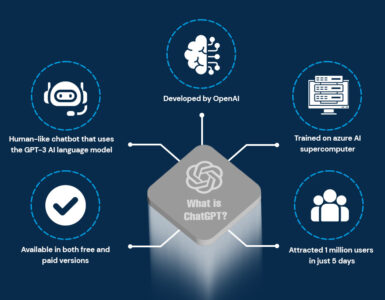

What are the major AI technologies?

1. Natural Language Generation 2. Speech recognition 3. Virtual Agents 4. Machine Learning Platforms 5. AI-Optimized Hardware 6. Decision Management 7. Deep Learning Platforms 8. Biometrics 9. Robotic Processes Automation 10. Text Analytics&NLP (Natural Language Processing) |

Another research by McKinsey estimates that logistics companies will generate $1.3-$2 trillion per year for the next 20 years in economic value by adopting AI into their processes.

Common Mistakes Behind Artificial Intelligence Failure

1. Using the Wrong Data

Most often business leaders get too excited and grab any type of data and try and use in their machine learning application. Data has to be free of defects but also have different parts to establish readable patterns.

2. Using AI as a Quick Fix

A lot of times your ERP has several functions that you are not utilising and find yourself now investing in more technology to perform a function that is already built in with your ERP.

Don’t rush to use AI unless you have full details of your ERP capabilities first.

Often, business problems exist because there’s an issue with an existing workflow or process. While AI may be able to help solve some of these roadblocks, it isn’t a band-aid.

More often, business process reengineering is required to truly understand and fix inefficiencies.

3. Operating in a Silo

If you’ve heard the term “operating in silos” before, then you know it’s not considered to be a good thing. The metaphor refers to people or groups that don’t share information or cohesively work together. This is the same for operating systems that don’t transfer data from one to the other.

This is where you get broken data that cannot be utilised or relied on to make strategic business decisions.

Often Companies quickly start projects and rush to meet requirements. Early successes are quickly overshadowed by the difficulty to adapt to additional feature requests, changing requirements, or new a set of customers with different needs.

We recommend including your operations staff in the project planning from the very beginning. These are the people who understand how it all fits together to eliminate the pain points of the business.

4. Emphasizing Technology Over People

The last 24 months has already been an emotional rollercoaster for many. Bringing technology in the business to replace an employee’s task can seem like they won’t be needed anymore. There are few employees who are great at accepting change and immediately see growth in these types of AI implementations.

However without a focus on organizational change management, some uneasy employees will be reluctant to learn and embrace new software.

Can AI Impact the Logistics Industry

If tasks and processes can be automated then businesses can then automate several back office tasks.

Some of these tasks are :

- Scheduling and Tracking

- Report Generation

- E-mail Processing

How is AI used in Logistics

In the logistics industry there is a deficit of time to review work before submission. This can be done if there is enough manpower to get the job done. There are only 24 hours in a day and only so much can be done whilst still having to be a responsible leader, parent, coach etc.

Manual capturing allowed you to only capture what is important at the time to keep the process going. Now its time to use AI to capture complete data so you can broaden your analysis of the industry and strengthen your business strategy.

Types of uses of AI in Logistics

- Back Office

- Vehicle Telematics

- Driver Profiling/Safety

- Demand Prediction

- Route Planning

- Automated Warehouses

- Delivery Automation

With the use of Data Entry Elimination tools such as AI and RPA Technology in back – office services, you have the opportunity to increase the quality of work and depending on your ERP system – exception reporting can assist you with quality checking of your data.

The use of these tools can ensure you have complete data captured in your systems rather than incomplete data.

“The ability to use AI to enhance decision making, reinvent business models and ecosystems, and remake the customer experience will drive the payoff for digital initiatives through 2025”

– By Gartner

Workflow automation, also called data automation means getting information into a system, launching tasks to process the data, and routing it to the correct people.

“Whether businesses are T&L providers themselves, or companies dependent on efficient supply chains for smooth operations – like retailers – embracing AI innovation is vital to be competitive.”

How will AI Implementation in businesses affect the Global Economy

A project undertaken by Price Waterhouse Coopers estimated that “artificial intelligence technologies could increase global GDP by $15.7 trillion, a full 14%, by 2030.”

China is making rapid strides because it has set a national goal of investing $150 billion in AI and becoming the global leader in this area by 2030.

How can SFL help you

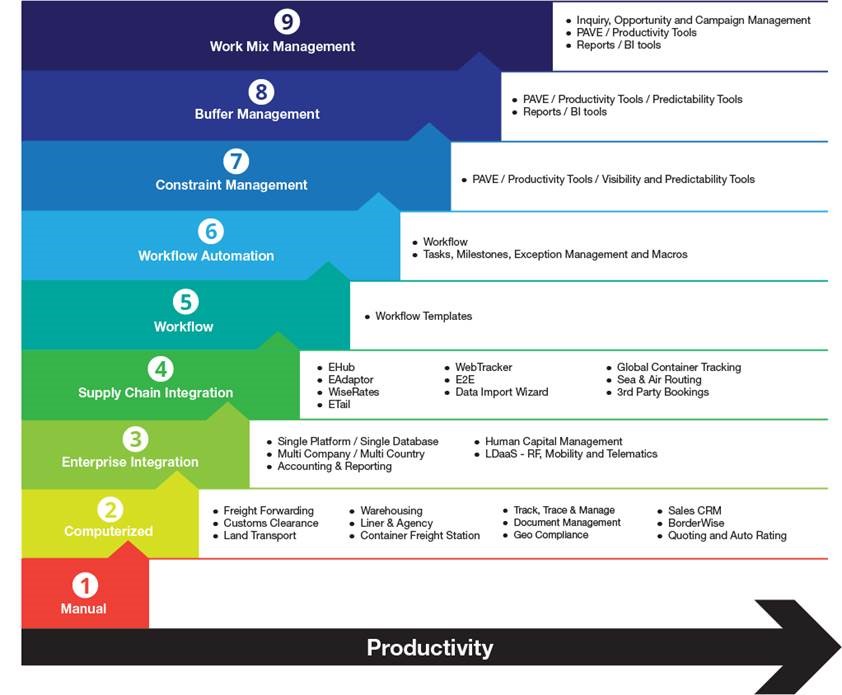

SFL Data Entry Elimination tools to be implemented at Stage 2 whilst SFL Visibility Tools can be implemented at Stage 4.

Contact us today at connectwithus@softfreightlogic.com to book a free consultation on your Digital Productivity Journey.